Home > Product > Home Appliance Mould > Air Conditioner shell Mould

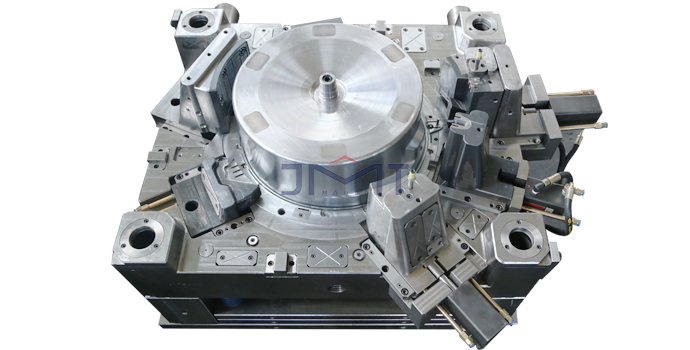

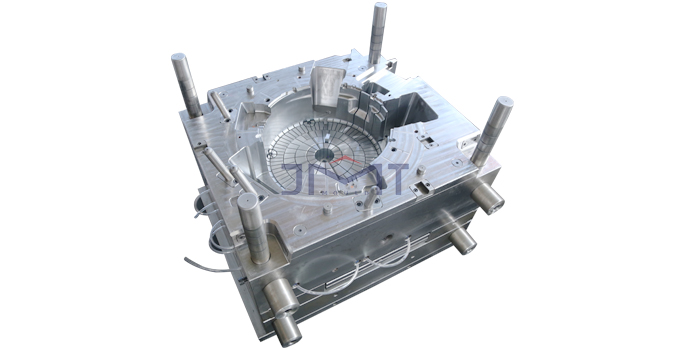

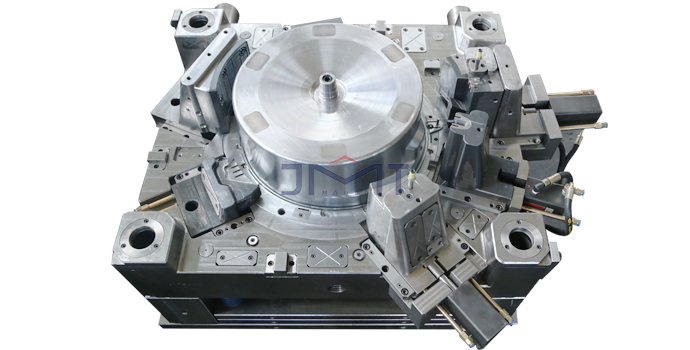

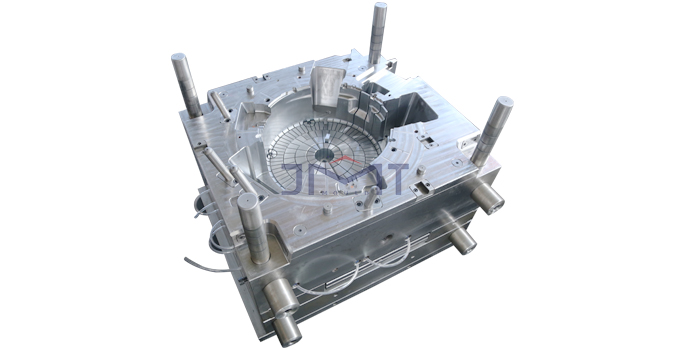

Air Conditioner shell Mould

JMT Air Conditioner Moulds are made of high-quality steel and are designed to produce plastic parts with high accuracy and consistency.

The air conditioner mold consists of two halves: the core and the cavity. The core and cavity are designed to fit together precisely to form the shape of the air conditioner housing. The mold is heated to a specific temperature, and then molten plastic is injected into the cavity under high pressure. The plastic is allowed to cool and solidify, and the mold is opened to release the finished part.

JMT’S well-made mold will produce air conditioner parts that are free from defects, have smooth surfaces, and meet the required tolerances.

JMT provide air conditioner shell mold, vertical air conditioner shell mold, wall-hanging air conditioner shell injection mold, hanging air conditioner shells mold, vertical air conditioner panel mold, hanging air conditioner panel mould, full set of vertical air conditioner plastic accessories mold, full set of air conditioner plastic accessories mold.

Mould Features:

1.Their molded product surface are without burrs, the internal non-onductive impurities, the material is enhanced polypropylene.

2.Post-treatment: nitriding (low nitridMold material: P20, 718, 718H, 2738, 2316, S136 and other materials for your choice, mold base: 45# pre-hardened > 30 HRC

3.Cooling system: optimized design of circulating water, improve production efficiency and reduce your cost

4.Mid-term treatment: mold quenching and tempering, mold heat treatment, etc., to improve hardness.

5.ing temperature, small deformation, high surface hardness (greater than HV850) and wear resistance without quenching)

6.Mold life: P20 normal use is not less than 500,000 mold times

JMT – your reliable mould expert! Welcome to contact and get quotes.

| Mould Name | Air Conditioner Mould |

| Plastic resin | ABS |

| Mould dimension (mm) | 1900X1180X1250 |

| Mould weight (T) | 18Ton |

| Mould cavity steel | NAK80 |

| Mould core steel | NAK80 |

| Gate system | 7 Tips YU DO Valve gate |

| Manufacture time (day) | 70days |

| Mould life | 800,000shots |

JMT Mould specializes in designing and making Air Conditioner shell Mould. From 2005 until today, JMT Mould has had many great achievements in Air Conditioner shell Mould development and manufacturing. Today, JMT Mould has over two hundred workers, including a mold design team of over 42 engineers.

JMT Mould has organized our facility for efficiency using the latest principles of lean manufacturing. Our capabilities now include prototyping, an injection workshop, and a state of the art QC lab. To help realize the benefits of consistent quality systems and business practices, JMT Mould invested the time and effort to be awarded the IATF 16949: 2016 & IS09001-2008 Quality Certification.

We are equipped with a set of advanced processing systems and fine machines, like CMM, Grinding, CNC Machines, Low-Speed Wire-Cutting Machines, EDM,. etc. We deeply believe that quality and speed are key elements to winning the competition. Advanced machines, not only can improve the quality continuously, but also shorten the production cycle and make customers’ products more competitive in the market.

Air Conditioner shell Mould Case Show

After years of development, JMT won the trust of customers in product development, manufacturing, after-sales service and technical advice. Want to learn more about car HVAC mold ?Get an online quote and mold DFM analysis today!