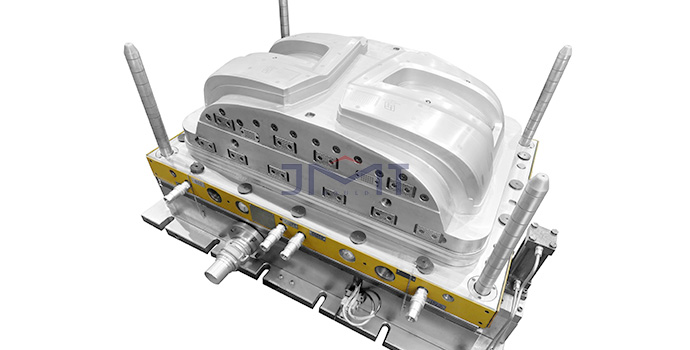

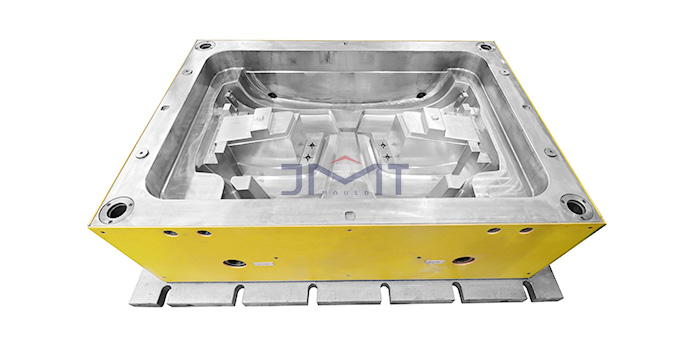

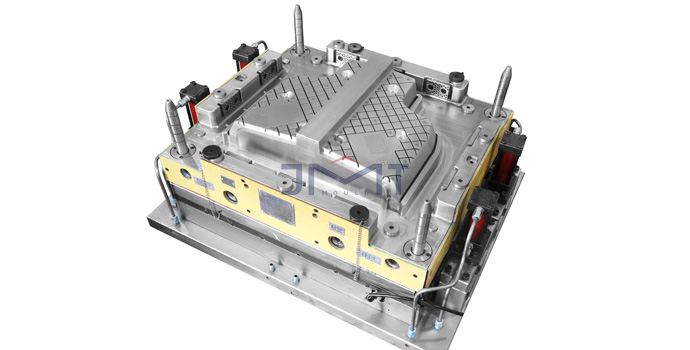

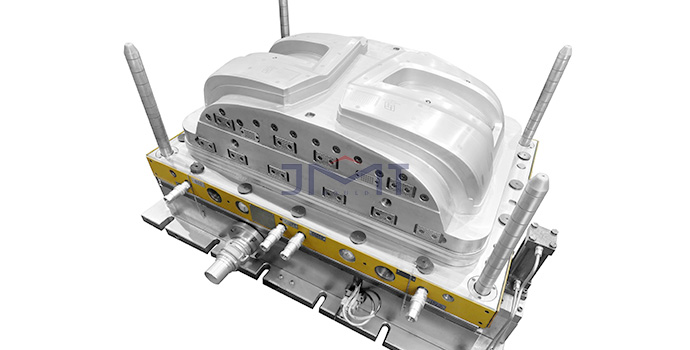

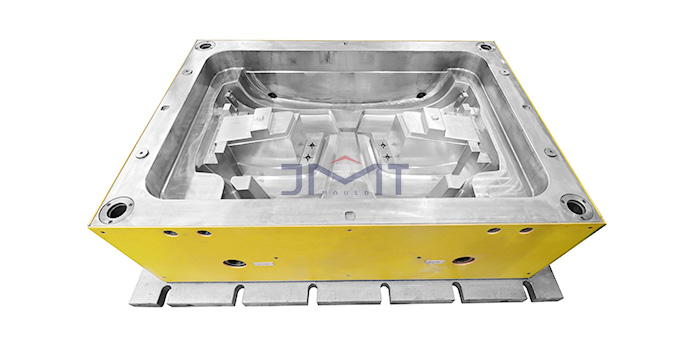

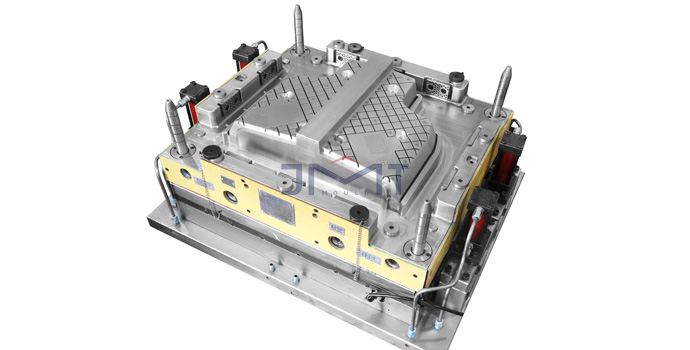

Home > Product > SMC/BMC/GMT Mould > SMC Sanitary Series compression mould

SMC Sanitary Series compression mould

Taizhou Huangyan JMT Mould Co.,Ltd(JMT MOULD)is a leading mold producer for SMC (BMC/GMT mould )mould Sanitary Series mould (Sink mould ,Door skin mould, shower base,SMC bath tub mould ) .

JMT MOULD in Taizhou ,zhejiang province .15 years for make compression mould (SMC moulds, BMC moulds, GMT moulds ) with 233 employees.

Our main products is sanitary series mould include SMC Sink mould ,Door skin mould ,Shower base mould and Bath tub mould .

JMT has a complete source for custom molding and molding design services and provides best service. No matter what mould it is,complex or simple , your projects will get the full attention in JMT . Starting from the drawing board to the completion of finished parts, we will meet or exceed your expectations.

On time’s mould delivery and good quality of the mould ,Mirror polish on the mould surface ,quickly feedback with customer that is why more and more customer choose JMT.

Long time for make SMC/BMC/GMT mould. Fit ,finish and function must be nothing short of excellent .

Product Name | Sanitary Series mould |

Product material | BMC /DMC/SMC/FRP/LFT/GMT |

Core&Cavity Steel | P20H |

Steel hardness: | HRC28-32 |

Mold Standard | DME |

Cavity Number | 1 |

Shaping Mode | Compression molding |

Heating System | Electric heating or oil temperature heating |

Cycle Time | 2-4 minutes |

Tooling lead time | 60 days |

Mould life | 10,0000shots |

Quality assurance | ISO900-1 |

Packing detail | wooden crate or according your request |

JMT Mould specializes in designing and making water heater mold. From 2005 until today, JMT Mould has had many great achievements in water heater mold development and manufacturing. Today, JMT Mould has over two hundred workers, including a mold design team of over 42 engineers.

JMT Mould has organized our facility for efficiency using the latest principles of lean manufacturing. Our capabilities now include prototyping, an injection workshop, and a state of the art QC lab. To help realize the benefits of consistent quality systems and business practices, JMT Mould invested the time and effort to be awarded the IATF 16949: 2016 & IS09001-2008 Quality Certification.

We are equipped with a set of advanced processing systems and fine machines, like CMM, Grinding, CNC Machines, Low-Speed Wire-Cutting Machines, EDM,. etc. We deeply believe that quality and speed are key elements to winning the competition. Advanced machines, not only can improve the quality continuously, but also shorten the production cycle and make customers’ products more competitive in the market.

SMC Sanitary Series compression mould Case Show

If you need more information SMC mold, please feel free to contact us.